3D Printing in Action

It’s a bird, it’s a plane, it’s a drone made with a 3D printer!

James I. O’Neill High School: Creating Real-World 3D Printing Products

Students at James I. O’Neill High School in Highland Falls Fort Montgomery School District in New York, under the leadership of school media specialist Sheri McNair, have moved beyond printing simple key chains and phone cases to creating working prototypes of real world products.

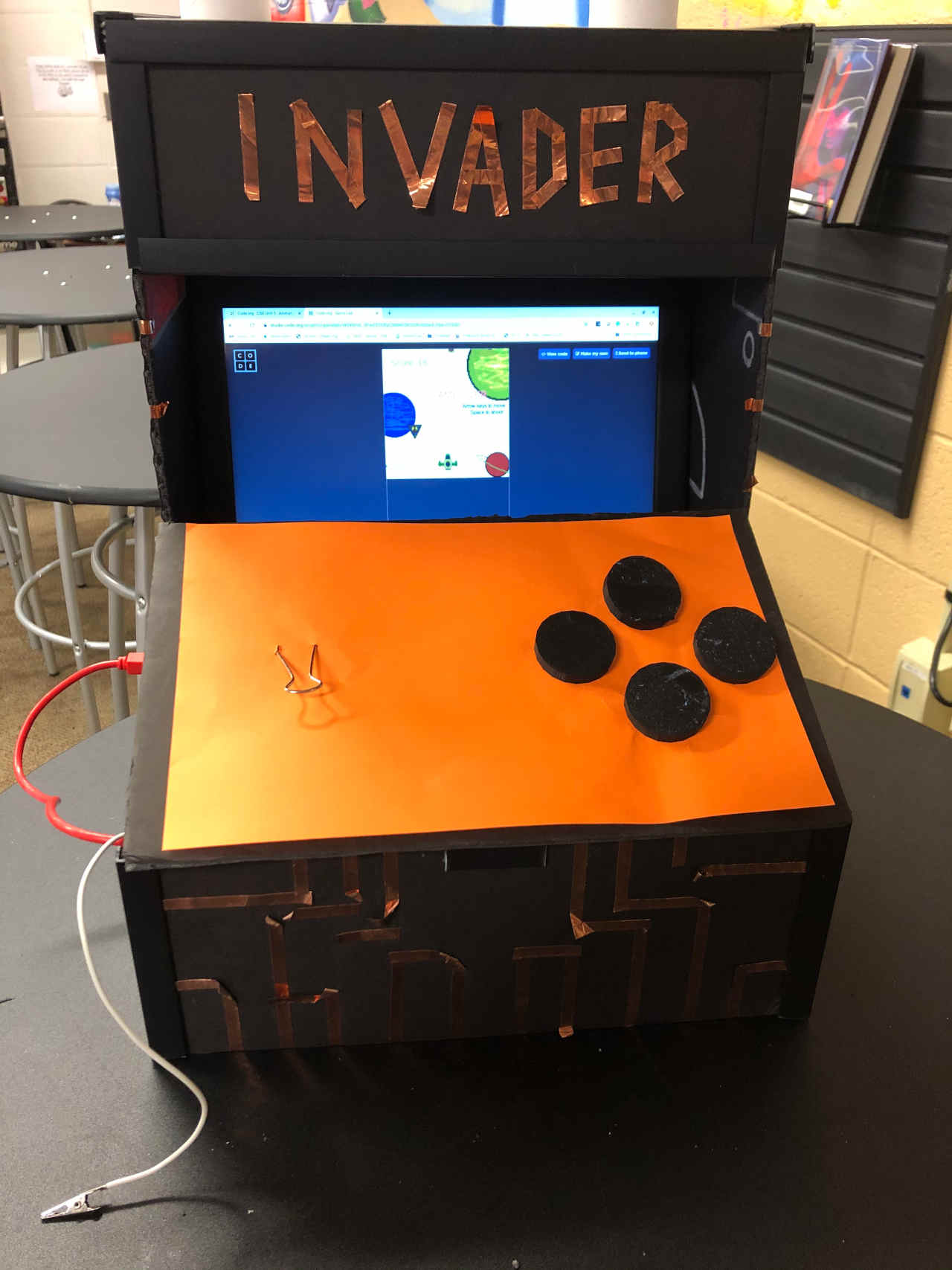

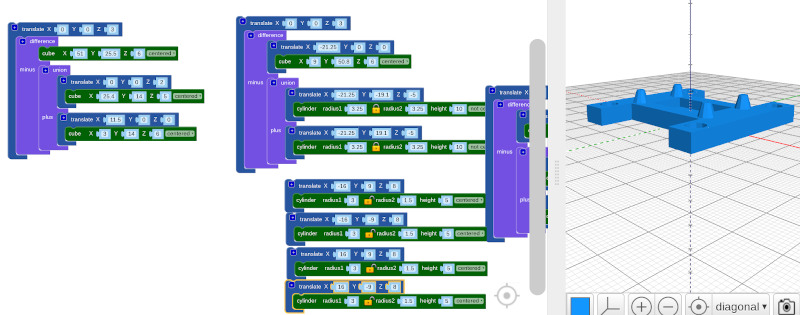

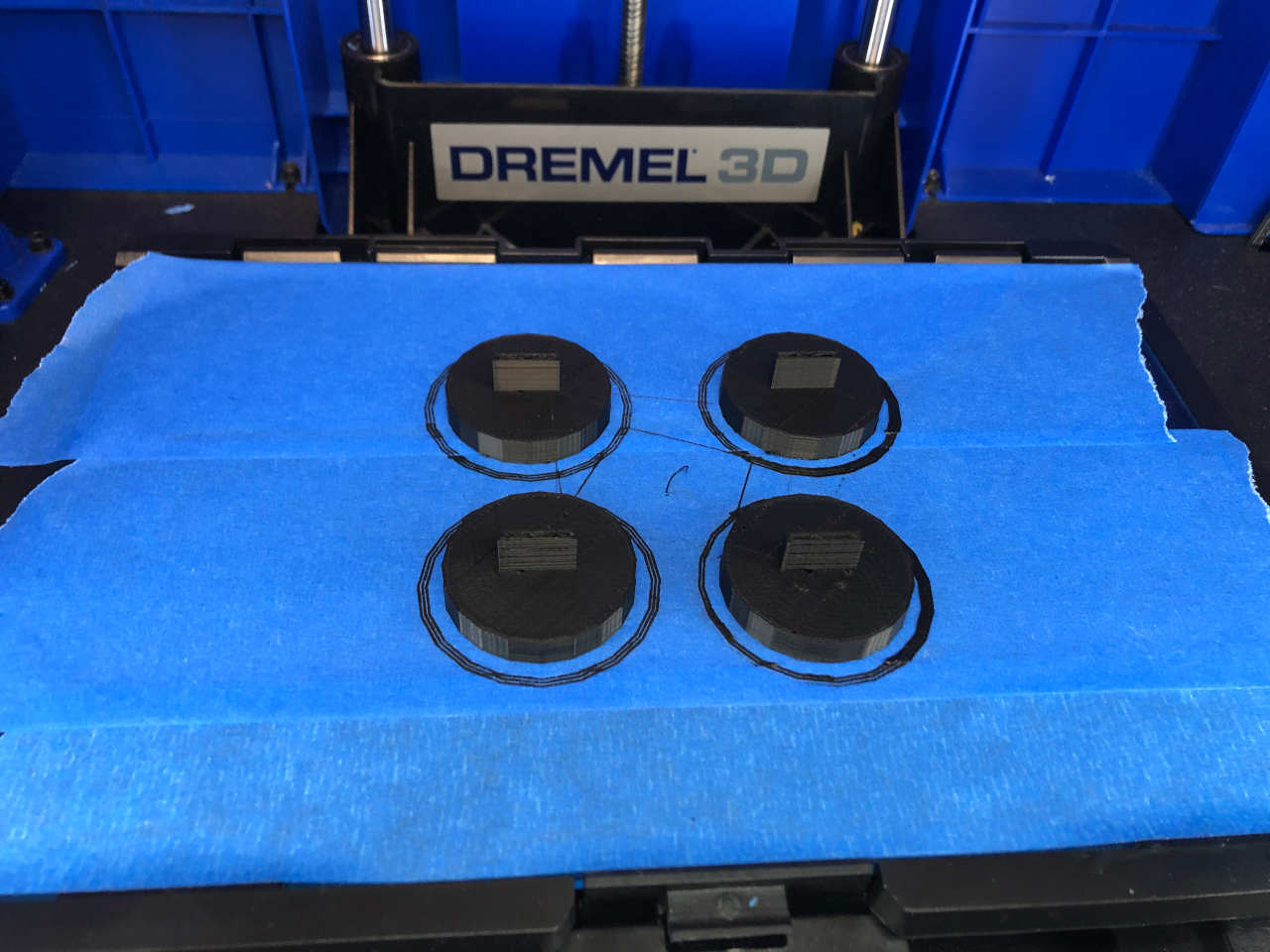

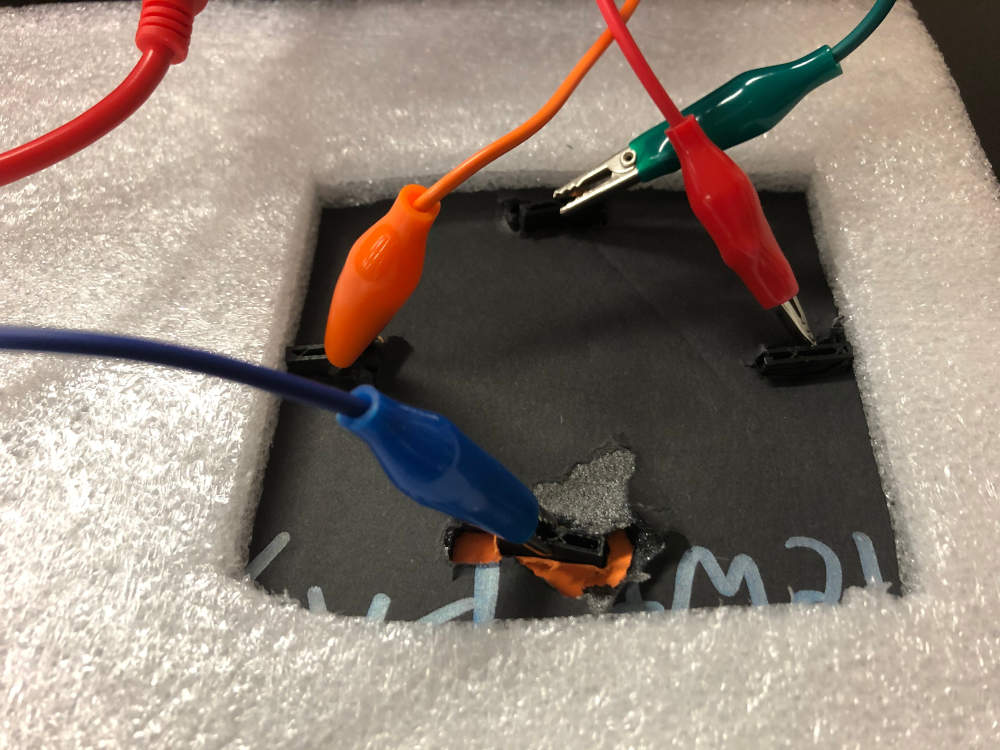

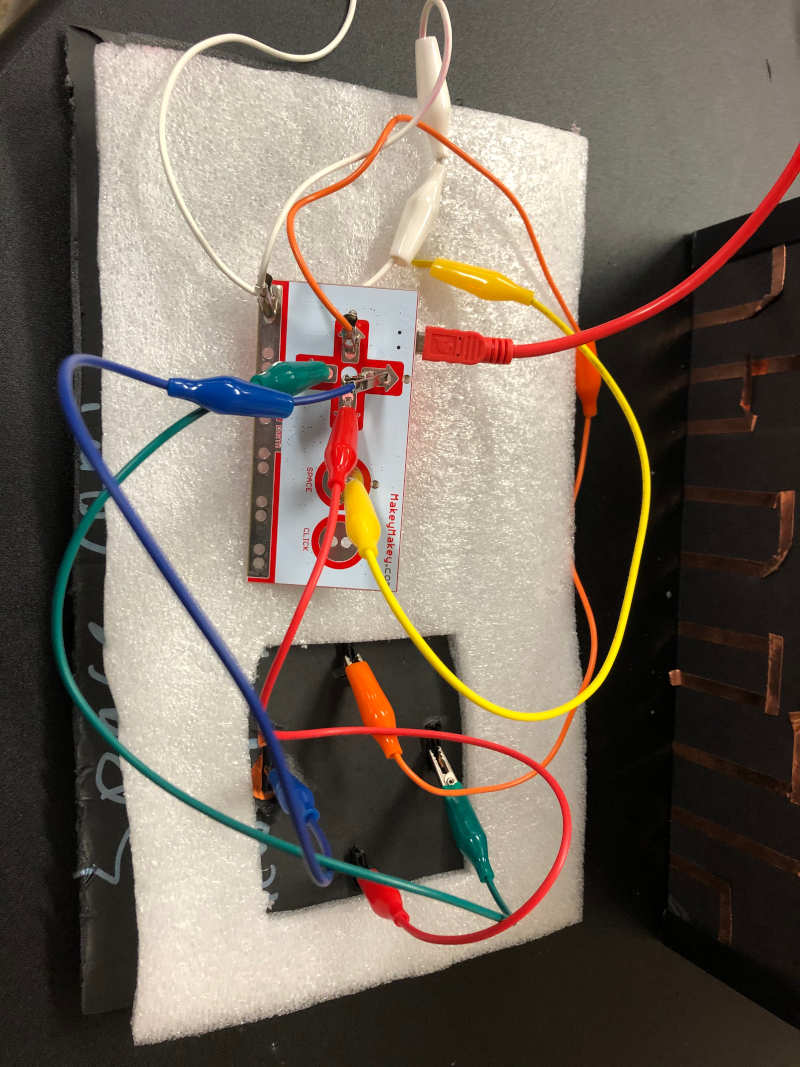

One project students in McNair’s Discovery CS & Coding course complete is to create an original arcade game combining coding, 3D printing, and fabrication. Student first design and code a video game on Code.org that utilizes the 4 arrow keys and spacebar for play. They then have to design and build a desktop-computer sized arcade cabinet to enclose and hide all but the screen on a Chromebook. Finally, using BlocksCAD, a cloud-based 3D modeling tool that utilizes block based programming, students create controllers for their games, which are printed using Dremel’s 3D40 and Protopasta’s conductive filament . The controllers are then attached to a Makey Makey , which in turn is connected to the Chromebook. This allows the conductive controllers to be “activated” and work as part of the cabinets build.

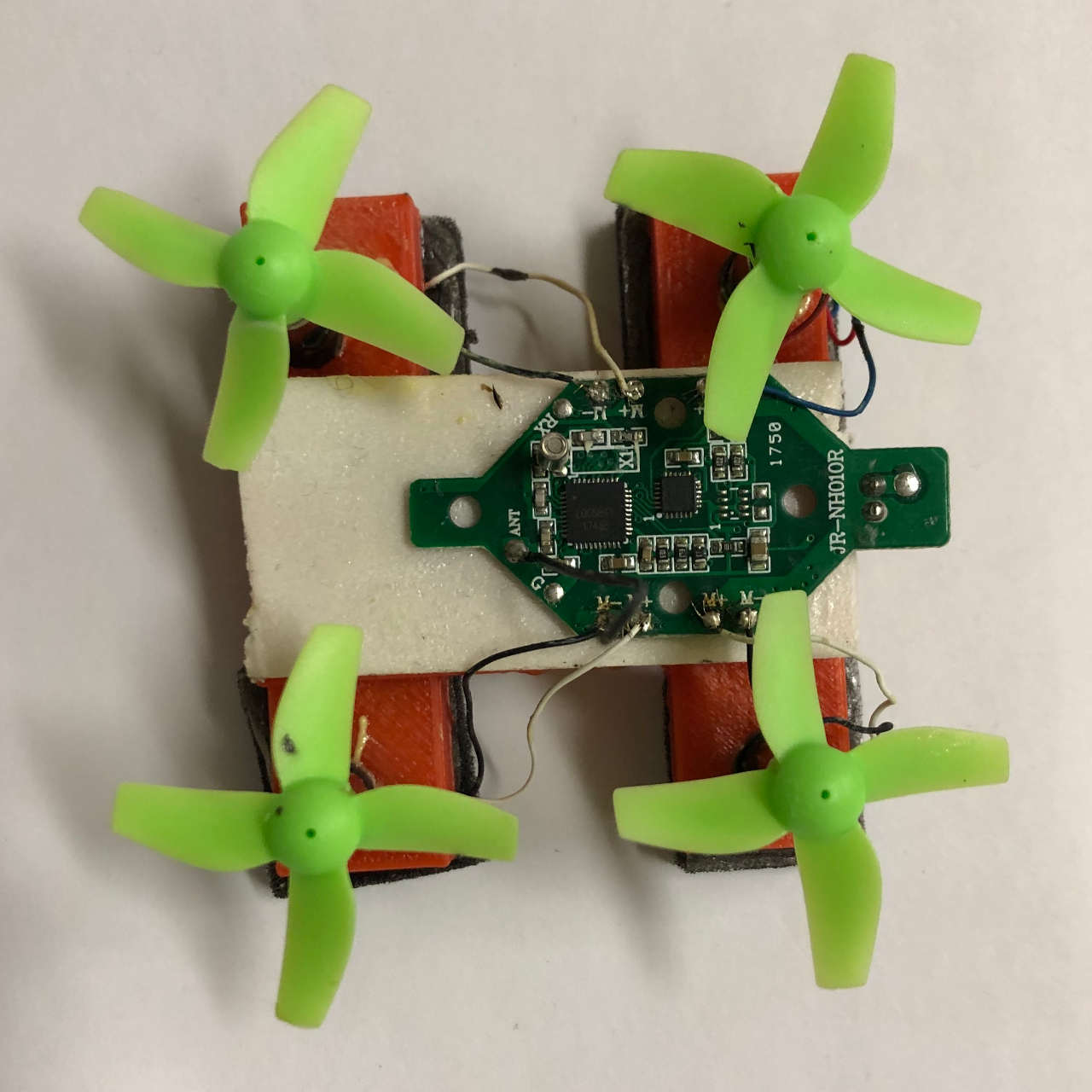

A second project students complete in McNair’s course is a building a working drone. Students again utilize BlocksCAD to code the design of a drone body, and print it on the Dremel 3D40. During this project students are working on design and coding skills, as well as learning about aerodynamics as they design a drone that needs to fly.

Rather than allowing students to print pre-made models, McNair requires students to design their own, accounting for things like weight of the finished product and its relationship with flight. According to McNair “Students learned quickly that they need to hollow out their designs, as many of the first attempts don’t make it more than a few feet off the ground. This type of hands-on problem solving allows students to break design problems down into their component parts, and learn from their failures.”

University at Albany: Taking 3D Printing to the Next Level

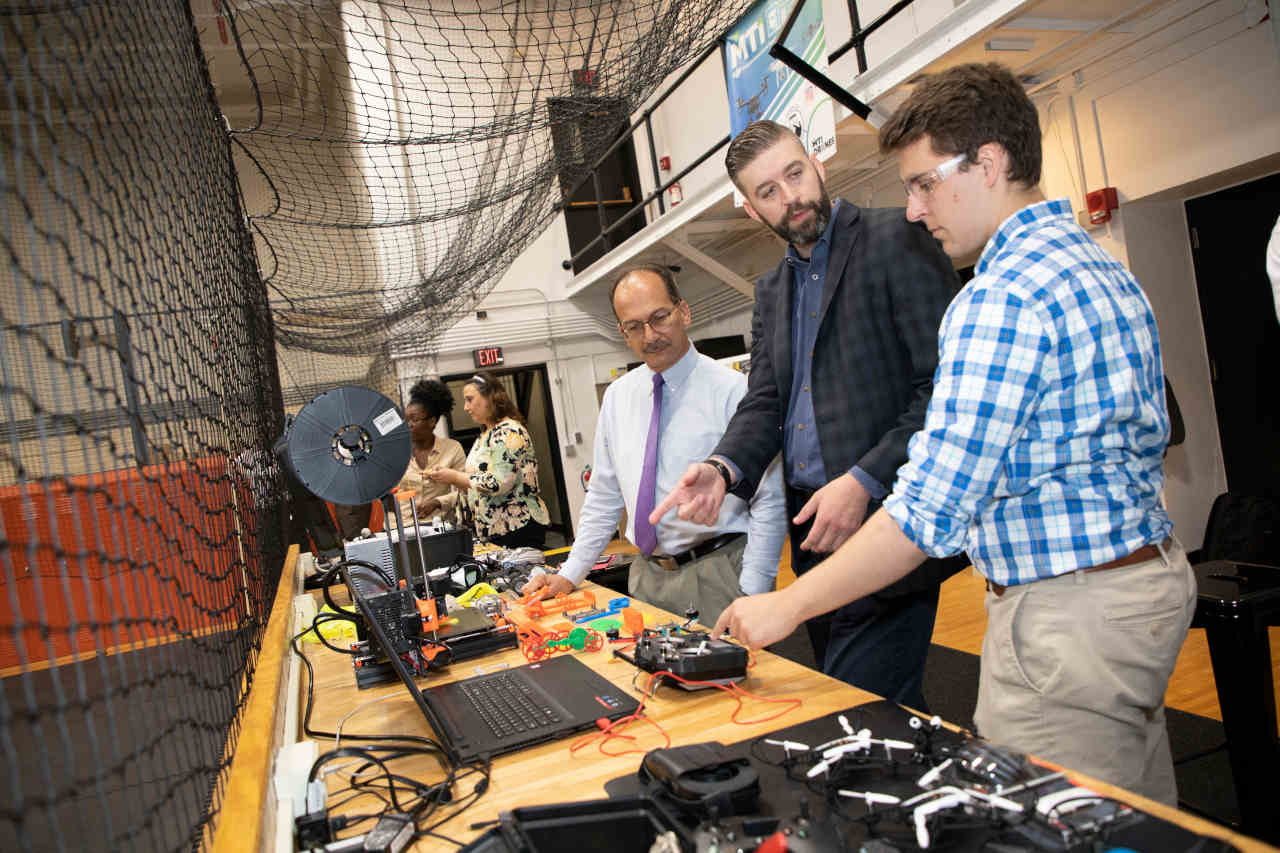

Under the guidance of Michael Leczinsky, a full time lecturer and director of the University’s makerspace, undergraduate students in the College of Emergency Preparedness, Homeland Security and Cybersecurity at the University at Albany have taken 3D printing to the next level, exploring customization and personalization to solve problems big and small.

Leczinsky credits the dramatic drop in costs associated with 3D printing with revolutionizing how we solve problems, stating “the sub $500 3D printers is a huge win for schools, libraries, makerspaces, hobbyists, and industry as it allows us to solve problems in entirely new ways. When we have a problem, technology exists to solve it. The rise in open source hardware and software is democratizing access to tools and innovation.”

The CEHC UAlbany Makerspace is equipped with Prusa i3 3D printers and AutoDesk Fusion 360. The Prusa i3 is based on the open source concept, and offers pre-built as well as build your own printers. Leczinsky describes Prusa printers as rugged and easily fixable - noting that with the amount of use the 3D printers in the makerspace get, the ability to print new parts when repairs are needed makes them ideal.

Tech & Learning Newsletter

Tools and ideas to transform education. Sign up below.

Students in Leczinsky’s courses, as well as students using the makerspace as hobbyists, are engaged in a number of projects as they learn to prototype products for real world problems. As students advance in their skills, the focus turns to solving problems big and small. From designing storage solutions, to creating vent covers for the makerspace’s laser cutter, Leczinsky explains “we may be creating low impact unexciting things, but the idea of customizing to solve your own problems is the focus.” Not all projects being created in the space are low impact, however.

Matthew Tyler, a recent graduate of the Emergency Preparedness and Homeland Security program, is working with local first responders to prototype and develop parts and modifications for first responder’s drones. The intent of the project is to develop modifications for existing drones to allow for additional sensors, actuators, and parts. According to Leczinsky “In one case, the part designed allows responders to attach lights to the drone so they can illuminate an area and provide better situational awareness and safety for the response team.” Leczinsky went on to describe additional projects such as equipping drones with speakers so that first responders can engage in two way communicate when responding in emergencies, or developing actuators that would allow first responders to use drones to drop life saving medical supplies, or even life rafts. Once the prototypes are approved, Leczinsky estimates they will be deployed across New York State to equip more than 200 drones with additional functionality, and will be used in daily emergency response activity.

Leczinsky explains “with reasonable computing power, and cost effective tools, anyone can learn to solve simple and complex problems. The underpinnings of our space are to help users learn to do just that.”

Choosing a 3D Printer

3D printing applications at the PreK-12 and college level offer opportunities for students to engage in real world problem solving, building, design, coding, and critical thinking skills that can be applied to 21st century problems. Choosing the right 3D printer for your students can lead to a world of possibility. Tech&Learning's 3D Printer Guide offers a detailed comparison of the best 3D printers for the education environment today. Not sure that a 3D printer is your best choice? Check out Tech&Learning's look at 3D printing pens for education.